Tekno RC’s Oil Bath Break-in System

Not only does an oil bath break-in save you time, but with proper maintenance, your engine will also last longer! Oil bath is regarded as one of the best ways to break-in a nitro engine since it reduces stress, improves engine life, and only requires a few short heat cycles before it is ready to race. Often it is recommended to replace the connecting rod after a typical “fuel” break-in due to stress; with the oil bath break-in, this is not necessary. When using an oil bath and proper care, engines last longer and stay at race speeds for many gallons.

Overview of a Typical Oil Bath Break-in

With the oil bath break-in, the engine is completely submerged in over 180 degrees Fahrenheit oil and driven by an electric motor with temperature, and speed adjustments made at specific time intervals. Varying the heat allows the piston and sleeve to break-in and seat at different positions, ensuring a more thorough break-in. The key to a proper break-in is finding when to make those adjustments and doing them at a precise time. Typically this is a time-consuming and tedious process as most break-in systems require manual intervention to adjust the temperature and speed. Furthermore, performing these tasks manually increases the chances for errors and inconsistencies from engine to engine.

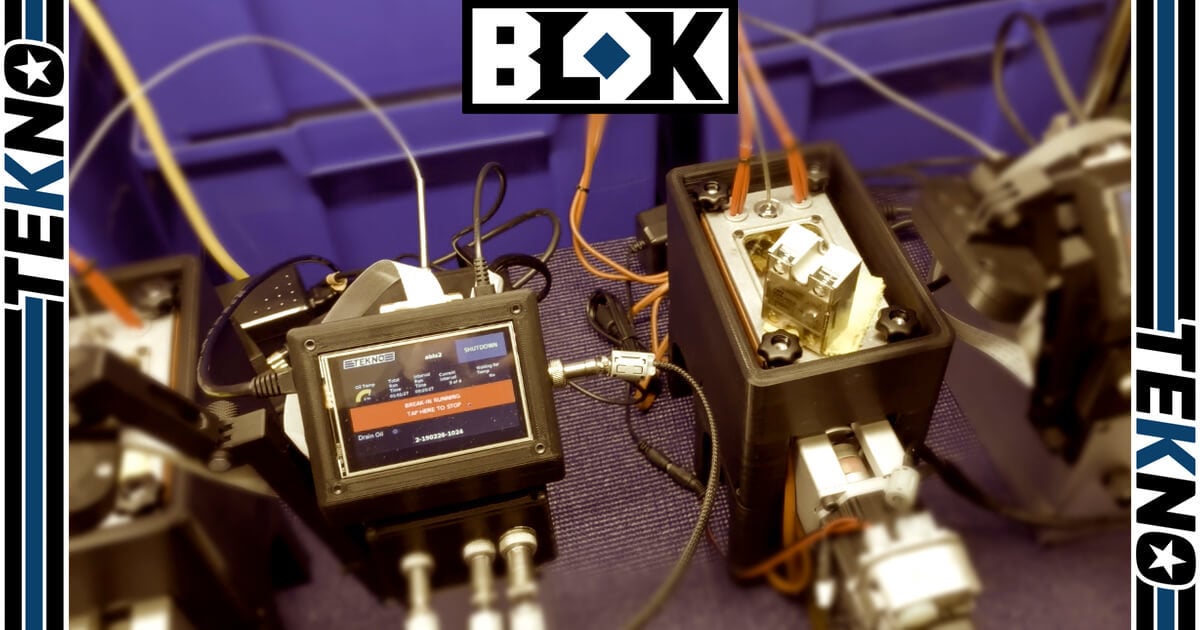

Our Oil Bath Break-in System

Our proprietary system makes a significant leap forward by completely automating the break-in process. Specially developed hardware and software ensure that adjustments are made precisely and at the proper time. Closed loop systems are used throughout to monitor the speed and temperature changes and shut down the system to protect the engine from improper settings or hardware malfunction.

Not only does our new system save time and eliminate the “human factor” but it also records data such as; the commanded speed and temperature, as well as the actual speed and temperature. Most significantly, it collects the pinch which is difficult to measure accurately. What we refer to as pinch is the torque output required by the servo motor to turn over the engine at top dead center. We tested many different methods to measure this before finally settling on one that is accurate, repeatable, and doesn’t generate additional heat.

With this data, our system then produces a graph and a report that we include with each engine. This report details the speeds, temperatures, and maximum pinch values so you can be confident the break-in was done correctly.

Completing the Break-in Process

When you receive the engine, there is a short process to complete the break-in before it is ready to race.

1. Fully install the engine.

Install the glow plug and mount the engine in your vehicle as you normally would with the exhaust pipe, flywheel and clutch.

2. Start the engine on the box.

Place your vehicle on the starter box, heat the engine to 200 degrees Fahrenheit with a hair dryer or heat gun and start the engine.

3. Make sure the engine idles by itself.

Slightly lean the top and bottom needles so the engine idles without additional throttle input.

4. Idle a half of a tank.

Idle one half of a tank through the engine while keeping the hair dryer handy and monitoring the engine temperature regularly. Try to keep it close to 200F at all times.

5. Let the engine return to ambient temp.

Once you have idled a half tank, stop the engine and let it return to ambient temperature before continuing.

6. Repeat steps 2 through 5 three more times.

The goal is to heat cycle the engine four times on the box.

7. Run the engine on the ground or track under low power.

Again heat the engine to 200F before starting it. Tune the engine so that it is about two to three hours fat on the top and bottom. You don’t want a full race tune at this point. While only using approximately 75% of the maximum throttle, run a complete tank through the engine while trying to keep the temp between 200 and 230F. Shut the engine down before it runs out of fuel and let the engine return to ambient temperature before continuing.

8. The engine can now be raced.

Heat the engine again to about 200F, start the engine. It should now be ready to receive a full race tune and be ready for a race.

We recommend always preheating your engine before starting, even after it has been run for several gallons. Preheating reduces stress from starting, helping to prolong the life of your engine.

All Blok Engines Are Now Oil Bath Broken-in for Free

The same oil bath break-in process previously only available to our team is now available to you! We use a proprietary automated process to ensure each engine is broken-in properly. All engines go through a series of carefully controlled time intervals where the speed and temperature are precisely adjusted. When you receive the engine, you only need to do a few heat cycles on the box, run a tank on the ground, and it’s ready for the track! Oil bath broken-in engines are in stock and available for shipment from our site or through our worldwide network of dealers.